APP

APP

手机站

手机站

产品详情

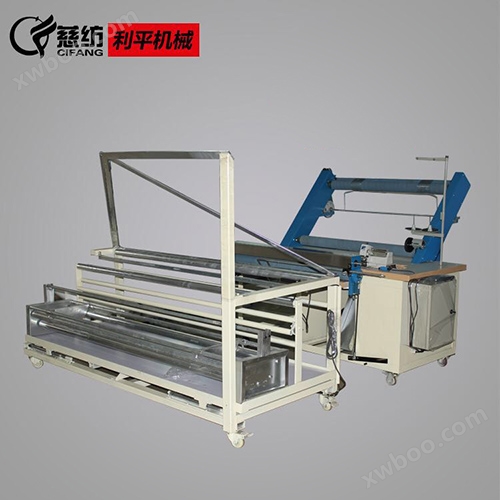

L-200PH 自动对折缝合机

Kl-200PH fold the split sewing machine

适用范围:

该机是我司根据市场需求所开发的一款新型对折缝合机,配合斜纹卷布机,切捆条机使用,代替传统的带刀缝纫机用人工对折后再缝布,大大提高工作效率。适用于各种布料、无纺布、泡棉、皮革、纸张等材料的对折缝合、切边、劈缝。 Scope: parameters: Voltage: 220/380 optional sewn cloth speed :0-650 m / h heating temperature :0-300 ℃

技术参数:

布料门幅:2.0米(另有2.4米,2.8米可选)

电压:220/380可选

拉布和对边电机功率:1.5KW

缝布速度:0-650米/小时

电热功率:0.2KW

加热温度:0-300℃

外型尺寸:对折架: 2.15米×0.85米×1.45米

拉布机:1.65米×1.25米×1.35米

配备特点:

1. 机头可选装:高速侧切刀平缝机、五线包缝机、超声波缝合机

2、带木板的放料架设计在对折架下面,既节省占地空间又可放整卷布料或者散装坯布。并带有有扩幅和对边功能,可将布料扩幅和对边后通过对折架将布料整齐对折并不产生皱纹。

3、拉布机构将对折后的布料送入缝纫机,缝合切边,经劈缝及热压装置,将布边劈开熨平,再经压布辊压死,拉布辊将布料拉出后,摆布架将布料摆成Z字形折叠起来。

4、采用智能温控器控制温度,温度精确。并配有米表,可计量长度。

5、缝纫及拉布由同一变频电机驱动,采用变频无级调速,能满足不同布料及速度的要求,同步性高,缝布速度可达每小时650米。

6、配有断线自动停机装置,断线或布料没缝合好都可自动停机。

7、配有定宽铁,保证整卷布料对折缝合后宽度一致。

8、配有自动收边料装置,可将切下来的边角料收卷起来。

This machine is our company according to market demand the development of a new sewing machine for folding split, with the diagonal rolling machine, cutting machine uses tie bar, instead of the traditional knife with a manual sewing machine sewing cloth and then folded, greatly improve the efficiency. For a variety of fabrics, woven, foam, leather, paper and other materials to fold stitching, trimming, split seam. Technical

Fabric width: 2.0 m (another 2.4m, 2.8m optional)

Labrador and on the side of motor power: 1.5KW

Electric power: 0.2KW

Dimensions: folded frame: 2.15m × 0.85 M × 1.45 M

Spreading machine: 1.65 m × 1.25 M × 1.35 M

Equipped with features:

1 optional head: high-speed side of the cutter sewing machine, five-thread sewing machine, ultrasonic sewing machine

2, with a wood frame designed to discharge below the fold frame, saving floor space but also put the entire volume or bulk cloth fabric. And the expansion rate and with a side feature, you can expand the width and the fabric edges by folding fabric neatly folded frame will not produce wrinkles.

3, Raab agencies will be folded into the fabric sewing machines, stitching trimming, sewing and pressing equipment by the split, side split ironing the cloth, and then crushed by the pressure roller, roll the fabric pull Raab out, the mercy of aircraft will be put into a Z-shaped fabric folded.

4, a smart thermostat controlling the temperature, the temperature accurately. And is equipped with meters, can measure the length.

5, sewing and Labrador by the same variable frequency motor drive, variable frequency stepless speed regulation, and speed can meet the requirements of different fabrics, synchronization of high speed sewing cloth up to 650meters per hour.

6, with a broken automatic stop device, suture break or a good fabric can not automatically shut down.

7, with a fixed width of iron, to ensure that the entire roll width of fabric folded suture line.

8, with automatic feeding device revenue side can be cut down and winding up of bits and pieces.

Twill tie of the production process: fold the fabric stitching